Beam type smoke detectors provide very successful protection in high ceiling areas. Since they are smoke detection detectors, they can be easily used if there is no steam, dust and smoke as a natural product of the process in the environments where they are used, that is, if there is no factor that can cause the smoke detector to give a false alarm.

There should be no physical obstacles between the receiver and the transmitter. While the conventional beam type smoke detectors require an unobstructed clearance of approximately 1m, a gap of 30-40 cm is sufficient for the next generation of double-beam and multi-transmitter beam type smoke detectors.

Usage areas in general;

Why a beam type smoke detector?

They are preferred for reasons such as ease of installation, offering a more economical solution in terms of installation and workmanship as compared to point-type detectors, ease of installation and better detection due to the cumulative effect in very high and wide areas.

In addition, the high number of device points to be used in the same area instead of beam type smoke detectors in point detector applications and access and intervention difficulties are also the reasons for the preference of beam type smoke detectors in high areas. They are more economical than air extraction smoke detectors that can be used in similar forms of areas.

Since there is no need for plenty of installations in the historical buildings with high ceilings, they can be preferred.

Which type is right for me?

You should review your detection system according to your facility's architectural features, ambient conditions and emergency strategy. In addition, although the economic conditions are also effective, it is more important than anything else to establish an accurate, healthy and useful perception.

The reflective beam type smoke detectors are relatively more economical than others. Therefore, they are usually the first choice. However, in the applications in the production halls, the beam direction setting may be impaired due to the vibration of the constructions where the beam type smoke detectors are installed for certain reasons. In such areas, motor type detectors are preferred instead of standard reflective type detectors.

In some production halls, high tanks or gallery cavities, it is possible that the light beam is easily reflected and creates an error condition and a false alarm. In addition, a much more dangerous situation is that the beam continues to reflect from other surfaces outside the protection area and does not generate an alarm even when smoke occurs. In the places where such situations may occur, receiver/transmitter beam type smoke detectors should be preferred.

In your ex proof environment, ex proof type receiver/transmitter type smoke detectors produced accordingly should be preferred.

TS/CEN EN54-14 manual and manufacturers' user manuals must be referred to for layout and installation details. There should be no direct sunlight coming to the receiver, transmitter or receiver/transmitter unit of the beam type smoke detector. This should also be taken into consideration during the installation.

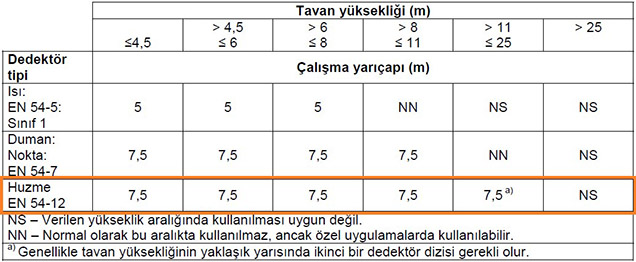

Hot air stratification, high air movements and detection difficulties in outdoor and wide areas should be well evaluated and the recommendations and directions of the standards should be followed. When necessary, a detector at a second elevation should be installed and detection weakness should be eliminated.